Commercial grade vacuum sealers for home users are generally considered to be the mid-level chamber style models. While these are not the huge industrial chamber machines you might see in large packing houses, they can be perfectly suitable for restaurants and other small commercial settings.

To illustrate, pictured at left is the VacMaster VP215, one of the best selling and top rated models on the market. (Click the image to view it on Amazon, or click here to read the complete VP215 review.) This is a table-top, chamber vacuum sealer, also often referred to as a “commercial” vacuum sealer.

Prices for a good chamber vacuum sealer range from around $650 up to $1,000 or so. However, heavy users will save over the long run because the bags are so much cheaper. Even if you buy in bulk, bags for channel (external) sealers will run you at least 10 cents each, whereas you can get chamber vacuum sealer pouches for about 6 cents each.

Why is a commercial vacuum sealer worth the price?

(continued below image)

One of the many advantages of these machines is in the way they work. Chamber vacuum sealers do not suck air out of the food bag. Rather, when the open bag is placed inside the closed chamber, air is pumped out all at once, keeping pressure equal inside and outside the bag until it is sealed. This is the main reason that chamber models work so well for processing liquids and very juicy foods. Soups, stews and sauces can be difficult if not impossible to seal with external vacuum machines, but chamber models handle them all just fine. The same holds true for any powdery foods like flour.

Food Safety

Always be sure you know how to handle, process, and store your foods safely. For an excellent resource, see this information from the National Center for Home Food Preservation.

For the more adventurous cook, a chamber vacuum sealer is required for certain culinary techniques such as vacuum infused fruits, or for creating that unique texture and appearance in vacuum-compressed fruits and vegetables. (Also see below about sous vide cooking.)

Another advantage is that these machines are built to last. Since they are basically designed for light commercial applications, they tend to hold up longer even with frequent use. Also, unlike suction type models, chamber vacuum sealers can be operated for much longer periods of time without overheating.

That brings us to one important choice in chamber units, which is whether to get a machine with a dry pump or an oil pump. Each has its advantages and disadvantages.

Note: For the ultimate in long term food storage, you may also want to check out HarvestRight Freeze Dryers for Home Users.

Dry Pump vs. Oil Pump

If you’re looking to save a little money, machines with a dry pump will cost you less. They are also maintenance free. The down sides are that they are noisier and slower, and they can not run continuously without overheating. That is, they’ll stay cool much longer than suction type sealers, but during very long periods of batch processing you may have to stop occasionally for a brief cool down. One example of a very good dry pump model is the VacMaster VP210.

A machine with an oil pump will cost you more, and it does require maintenance. Whether you consider the upkeep significant may depend on your circumstances. Generally speaking, a new chamber sealer will need an oil change after the first 25 hours of use, and thereafter it needs changing about every 60 hours. The process is not complicated at all, and if you hate reading instructions you can even find videos showing how it’s done.

On the plus side, chamber sealers with oil pumps will run faster and quieter and will stand up to continuous use without overheating. For an example see the VacMaster VP215 mentioned above. Many people also have more confidence in the longevity of these machines simply because anything with an oil pump tends to last. It’s definitely a good choice for anyone planning on doing lots of prolonged batch processing, such as packaging bushels of fresh produce at harvest time or vacuum sealing game at a large hunting club.

Do you have enough room for a commercial vacuum sealer?

For most home users, one important consideration will be space. A typical unit can be around 14 or 15 inches wide, 20 or more inches deep, and 15 or more inches tall. That’s quite a chunk of kitchen counter space!

You also need to keep in mind the clearance needed if you have overhanging cabinets. One model, the VacMaster VP112S, is shorter than other models and has a hinged lid designed so that it doesn’t require as much overhead clearance.

These units are also pretty heavy to move around, anywhere from about 50 to 80 pounds. One good solution is to place it on a rolling cart, especially if you have a pantry or nearby storage room to move it out of the way when it’s not in use.

Do you need a chamber vacuum sealer for sous vide cooking?

The simple answer is no (but keep reading). Technically, you don’t need any kind of vacuum sealer to do sous vide cooking. You can fill a zipper top bag with your food, then slowly lower the open bag into a bowl of water to force out air, and then zip it shut. One problem with this is that it doesn’t always work perfectly for getting out all the air, so you can end up with floating bags and unevenly cooked food. Another problem is that it’s only okay for low temperature cooking because ordinary zipper type bags aren’t safe for higher temps.

With a small investment, you can be quite successful using a channel type or even a cheap hand-held vacuum sealer to create your sous vide pouches.

On the other hand, very avid sous vide cooks may consider a chamber vacuum sealer a necessity because it offers you more options. You can cook foods with any amount of liquid – custards, stews, meat and seafood in oil or lots of sauce. You may also experience better results with lots of other sous vide dishes simply because the pump on chamber models will extract the maximum amount of air possible from the food pouches.

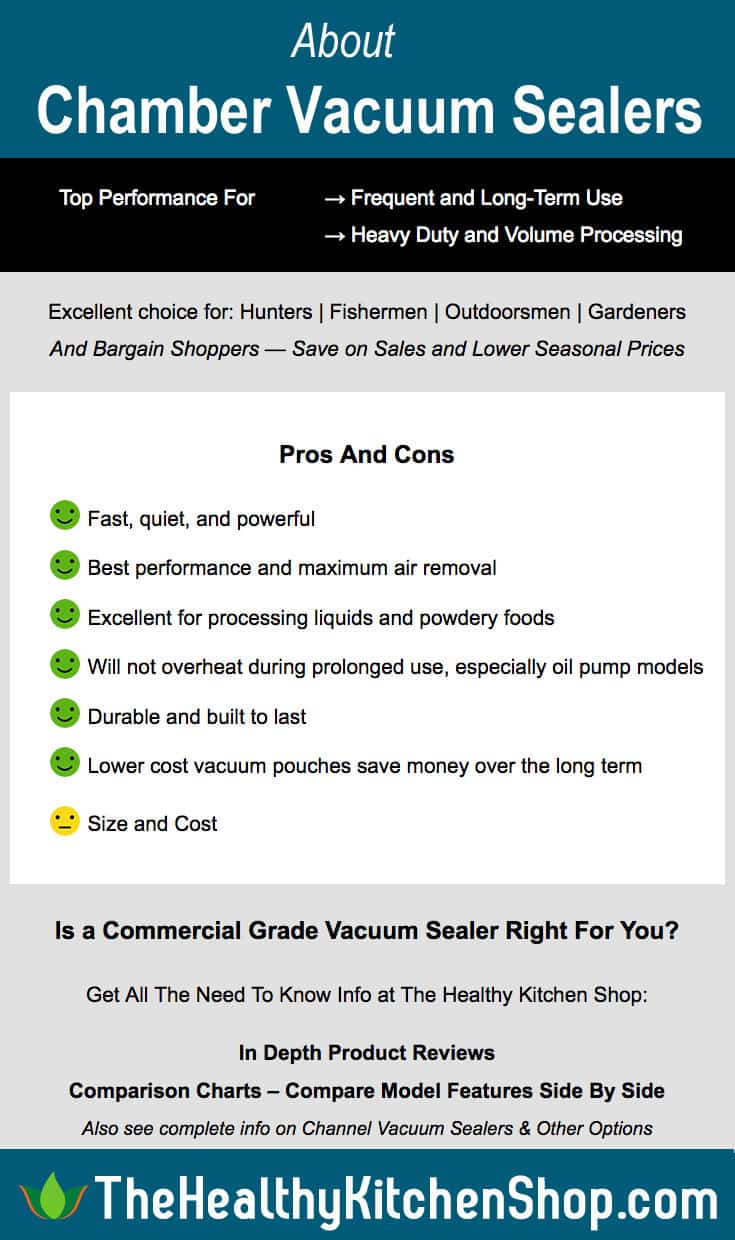

Summing It Up: Is a Commercial Vacuum Sealer Right For You?

Pros

- Fast, quiet, and powerful

- Best performance and maximum air removal

- Excellent for processing liquids and powdery foods

- Will not overheat during prolonged use, especially oil pump models

- Durable and built to last

- Lower cost vacuum pouches save money over the long term

Cons

- Much costlier than suction type sealers

- Quite large for both use and storage

- Heavy and not easily moved

- Oil pump models require occasional maintenance

In a nutshell, the only real drawbacks are size and cost. If you’ve got the space and the budget, a commercial vacuum sealer is an excellent choice for anyone interested in frequent and long-term use. In fact, it’s a requirement for very heavy duty processing, especially when that involves vacuum packaging large batches of food at once. The investment will definitely pay off for hunters, fishermen and other outdoorsmen, and for gardeners at harvest time, and for anyone who likes to buy in bulk to take advantage of sales or lower seasonal prices.

How to Find the Best Commercial Vacuum Sealer For You

Start Here → Chamber Vacuum Sealer Comparison Chart

You can compare features and prices side by side, and you’ll also find links to the complete reviews that will give you all the details on each model.

You may also want to consider…

Channel Vacuum SealersIf a chamber model is more than you want or need, a channel vacuum sealer may serve your purposes. To find out more, start with this overview:

Channel Vacuum Sealer Comparison Chart

On that chart you’ll find links to the complete review of each model.

Top

Top

Leave a Reply